SURFACE FINISHES

The final surface of shotcrete can have many types of finishes: Normal gun finish, screeded surface, wood float, sponge finish, steel trowels, patterned finish (blockwork, masonry), simulated “mock rock” and simulated pre-cast panels.

A raw shotcrete surface is usually quite uneven and rough. This is known as a ‘gun finish’. This is the most economical surface finish and is usually satisfactory for structures such as tunnels, mines, and stabilised slopes that are seldom visible to the public. However, this type of finish is often unsuitable for structures that are highly visible, and for this reason, a variety of surface finishes have been developed that are more aesthetically pleasing. Almost any finish is possible for a shotcrete structure; however, finishing is a labour-intensive activity and therefore will increase the cost of the structure.

Most finishes are implemented to improve the aesthetic appearance, but others are produced for the purpose of improving the function of the surface, such as reducing friction for passing water or air. The basic gun finish is typically pitted as a result of the impact of aggregate particles into the wet surface during spraying. This finish is not suitable for many applications, such as high-traffic pedestrian areas, water tanks, and any structure requiring straight edges. When a more geometrically regular surface is required, a screeded surface can be produced by running a straight edge over the surface while the concrete is still wet to create a desired profile.

A screeded surface is suitable for cavity walls, air plenums, pools, and tanks that require a secondary lining of tiles, render, etc. A screeded surface may match a profile, but the surface is not closed and includes aggregate drag marks caused by the screeding process. Screeding is therefore often followed by floating to close up the surface. Wooden floats and then sponges can offer a render-like finish, or steel trowels can produce a glassy finish. Areas where a sponge finish is suitable include car parks, basements, and pedestrian-accessible areas.

A steel trowel finish is best for tanks, drains, watercourses, and floors. Another option is to spray and dust the screeded surface whilst the shotcrete remains wet. This will offer a more uniform and controlled gun-like finish.

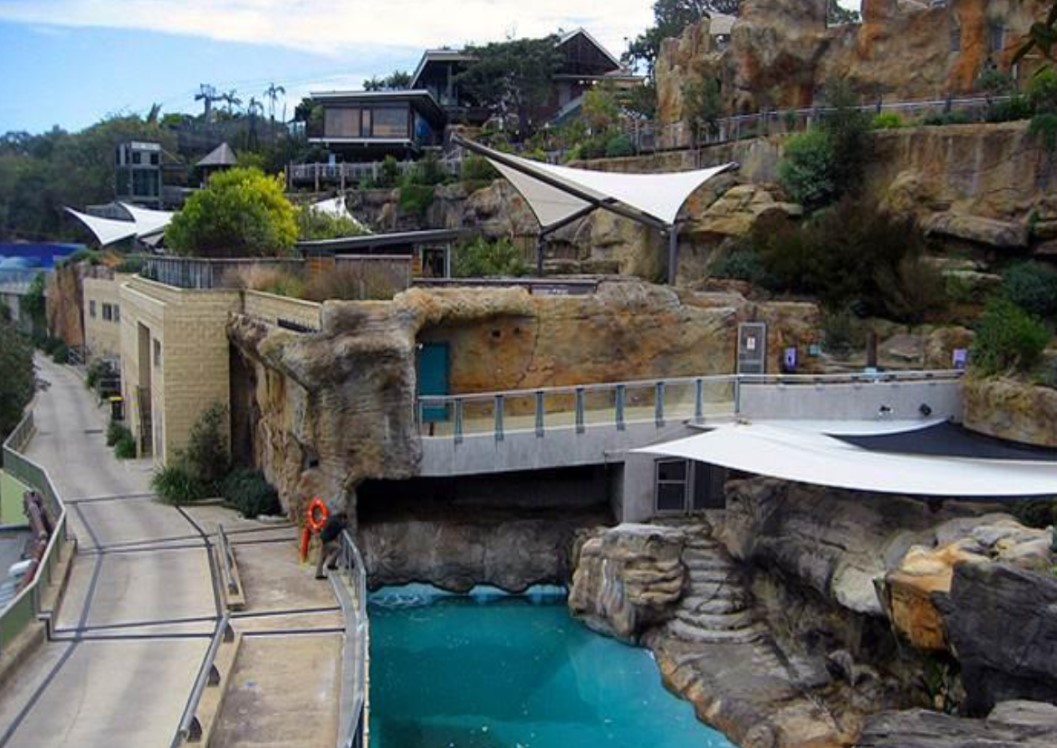

Another alternative to smooth finishes is patterned finishes, usually intended to resemble cast concrete or pre-cast panels, or a non-concrete surface such as masonry or blockwork. A ‘cast’ concrete surface usually requires a high degree of smoothness and flatness, with careful attention to jointing or grooving. Slope batters, retaining walls, bridge abutments, and the like can be made to resemble pre-cast concrete panels very effectively. Other applications that are suitable for patterned and simulated rock include road cuttings, zoos and theme parks, water features, pools, and ponds.

Patterned surfaces can be created through the use of stencils or hand-trowelling. Masonry, blockwork, and other repetitive patterns can be aided through the use of stencils. This can be particularly effective for retaining walls and marine walls. All types of patterns are usually made more attractive by introducing colour to the surface. This can be done by including oxides in the base concrete, and/or spray-on coloured stains and paints that introduce local variations that more accurately reflect the variations in both natural and manufactured surfaces.

Simulation of native rock (also called ‘mock rock’) is a special skill that requires a high degree of artistic creativity and technical skill in sculpting, blending colours, and creating surface textures. The base concrete can include a basic oxide colouring. The artist then blends additional oxides, stains, and paints into the surface to create local variations. When the sculpting is completed, the surface is often etched with acid to produce an ‘instant weathered’ appearance.

Application of Shotcrete

Most non-gun finishes can only be achieved using shotcrete without a set accelerator. When creating shotcrete walls with a specified minimum structural thickness, over-break on the back face of the wall (usually arising from an irregular or over-excavated ground profile) must first be evened out so the surface that is to receive the structural shotcrete is sufficiently flat and smooth. The in-fills sprayed to create the smooth back surface are sometimes referred to as ‘dental shotcrete’. Both the dental and structural shotcrete can be set accelerated to assist placement, but the final shotcrete layer must be non-accelerated to allow time to create the desired finish.

Fibre reinforcement is not recommended when a non-gun finish is required. Fibres interfere with screeding, floating, and trowelling and make most finishes much more difficult to achieve. Steel fibres should not be used when any specific aesthetic finish is required because corrosion of steel fibres located close to the surface will cause pop-outs, rust stains, and streaking.

LINK: Concrete Institute of Australia - Shotcreting in Australia